No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Télécharger votre configuration en PDF

/ EXALT 24 DISC BRAKE - carbon

New product

They are the most extreme climbing wheels ever built. The latest technological breakthrough such as the new M40J carbon fiber and a special carbon core are used to manufacture this rim. Their ultra responsive feeling and extreme lightness make them so cool to ride. EXALT 24 DISC BRAKE comes as standard with the made in France RAR ESO DISC BRAKE hubset.

Data sheet

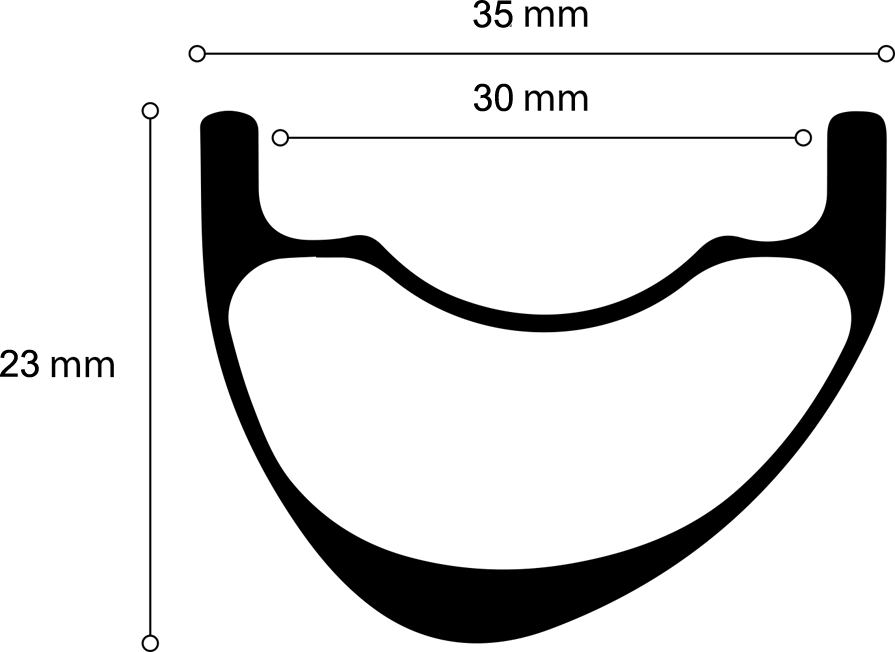

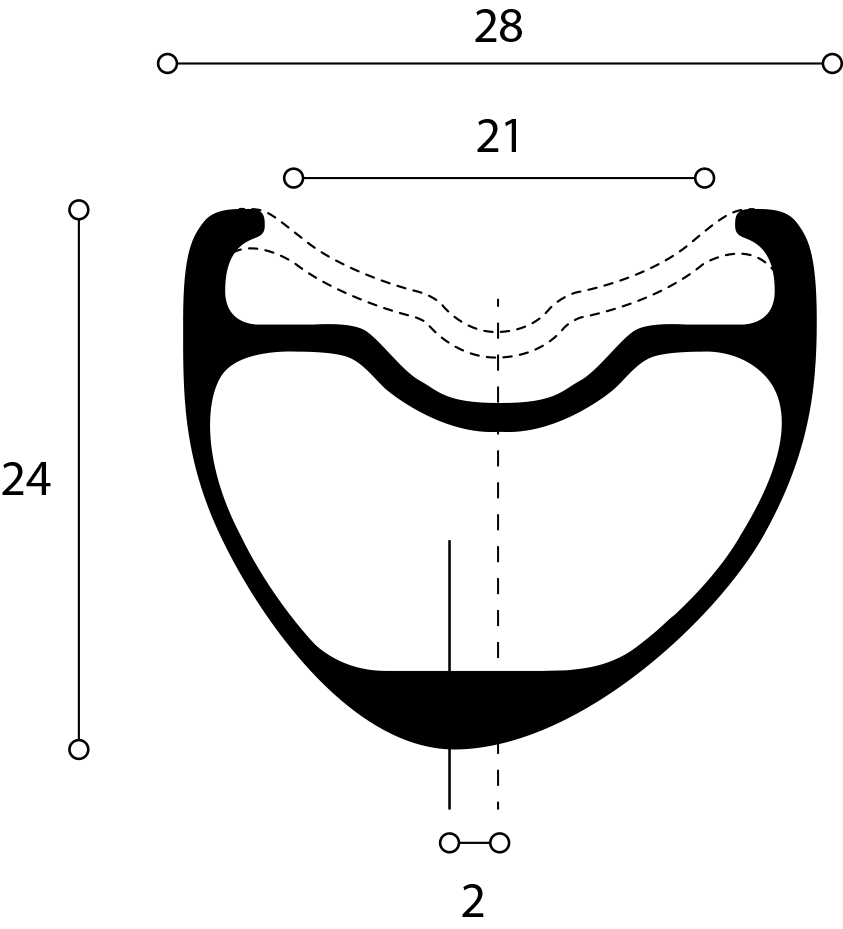

| Rim depth : | 24mm |

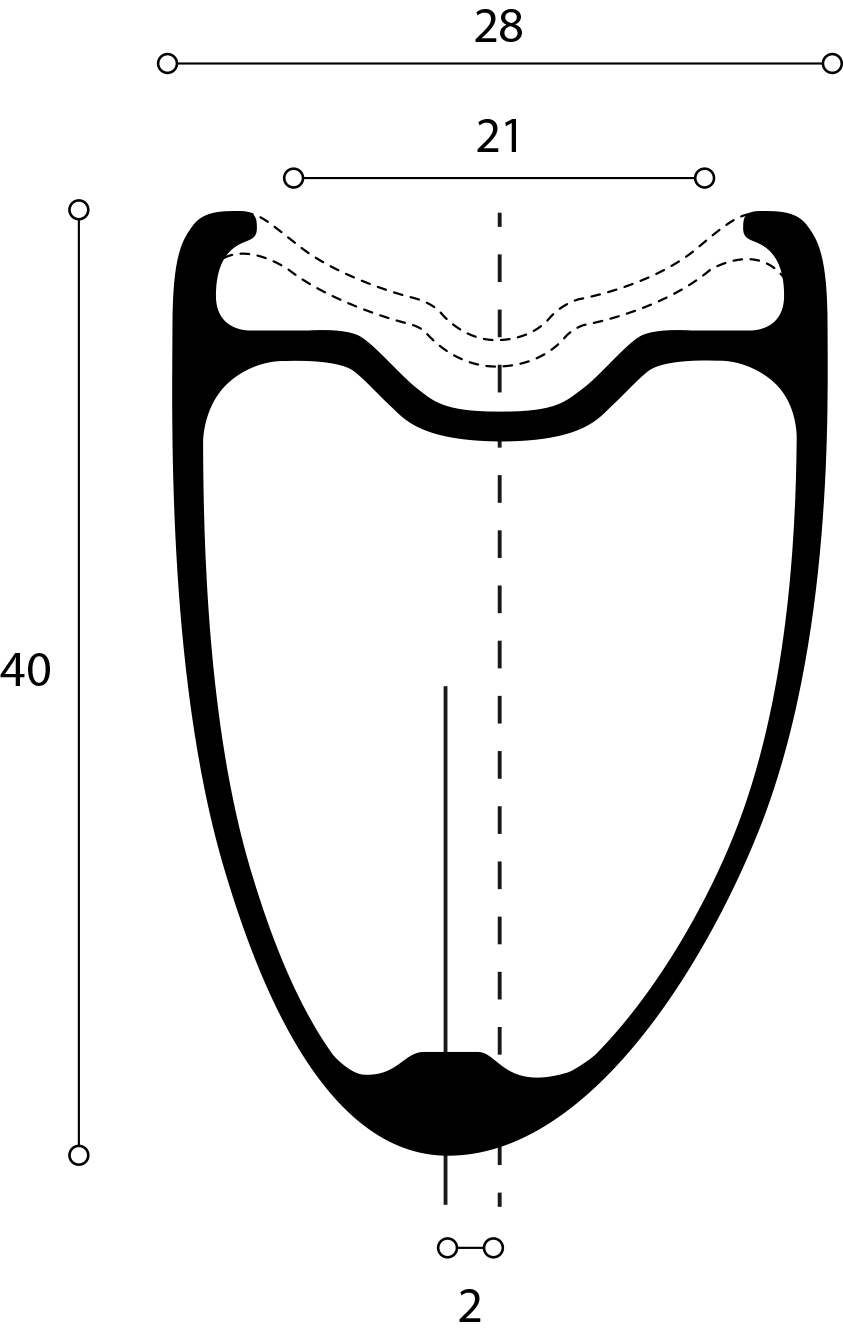

| External rim width : | 28mm |

| Internal rim width (tubeless/clincher): | 21mm |

| Weight / set - RAR ESO hubs (g) | 1140 tubeless - 960 tubular |

| Front wheel hub : | RAR ESO |

| Rear wheel hub : | RAR ESO |

| Disc rotor standard: | Center-Lock |

| Warranty : | 5 years |

| Weight limit (rider+bike): | 85kg Contact us for bespoke ABSOLUTE wheels if you exceed this limit or if you prefer super stiff wheels. We will beef them up with different parts and higher spoke count. |

More info

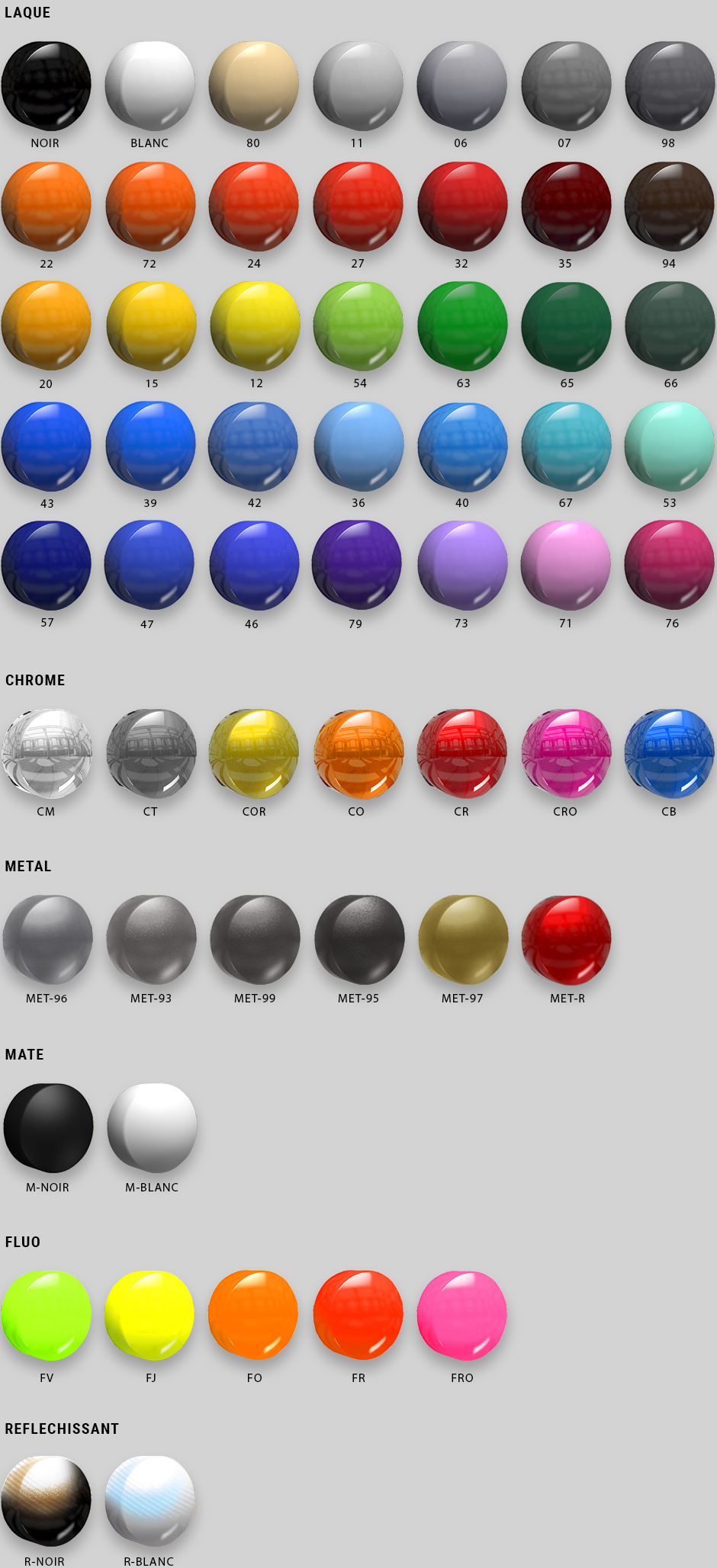

COLOR CHART

Let us know which color better suits your bike in the commentary section at step 3 of the ordering process.

Example logo CHROME-MIRROR

Example logo RETROREFLECTIVE black

NIPPLE TINT

Beyond these colors, we can lace your wheels with customized coloured nipples.

Have a look !

From left to right:

BLACK - GREY - SILVER - GOLD - ORANGE - COPPER - RED - PURPLE - MARINE BLUE - TORQUOISE - GREEN

Example purple nipple + black mat logo + painted Crystal blue spokes

OPTIONS UPCHARGE:

Logo color: coated or mat is free of charge. For other colors, please refer to the option menu top right of this page.

Nipple color: free of charge.

Paint for spokes / rims / hubs: please refer to this page: https://www.roues-rar.fr/en/852-paint-options.html

RAR EXALT

10 years.

A fascinating, complex and instructive evolution.

"LET'S BREAK THE CODES. "

With outstanding products.

With technical and precise explanations.

Here, we tell you why our rims are designed then built by composite specialists, twith carefully selected fibres, using the latest state-of-the-art tooling, through a controlled process.

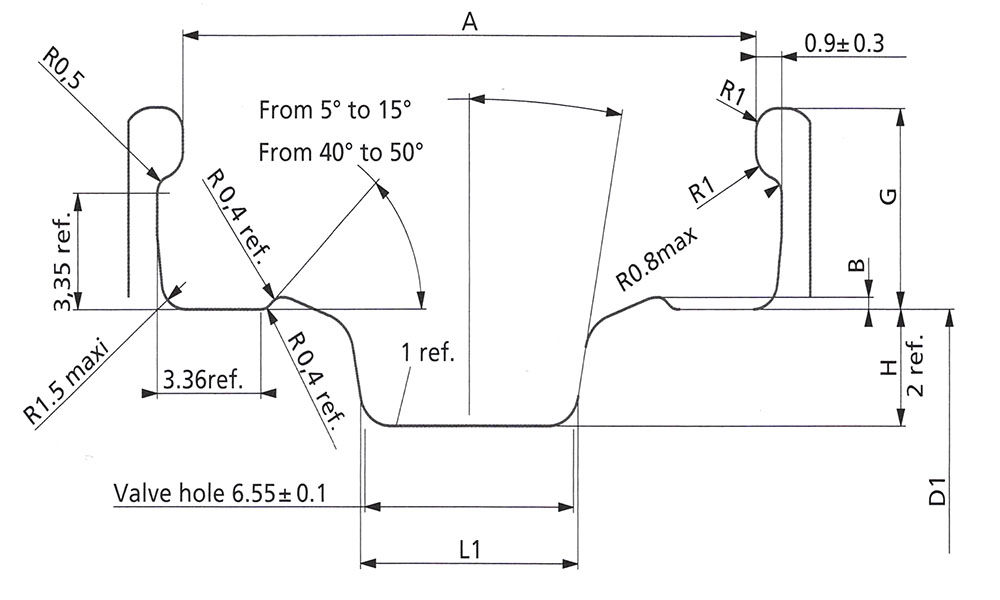

DESIGN

From scratch: this is the most exciting stage.

The product must be as extreme as possible, combining aesthetics, construction ease and strong geometry.

This first step sets dimensions, draws curves and shape.

DOUBLE CORE TECHNOLOGY

The production of a light rim is rather common: simply reduce the amount of material. Two birds with one stone: not only do you reduce weight but also material and labor as well.

The production of a light and tough rim is more complicated. It is all about strategically lowering the number of layers and-or replacing them by better performing fibers.

Producing a light, tough and stiff rim now requires this special ingredient : better ideas !

The innovation behind our "double core" technology is made possible by a unique process.

While a commonly built rim is made into a steel tooling made of 2 main pieces, plus 3 to 5 circle segment, our EXALT is designed upon several other parts which specifically optimizes the material thickness and its regularity all along the critically stressed regions.

This breakthrough revolutionizes our production.

The result is amazing. The rim is super reliable, with a very high impact resistance, while its weight is ultra low.

GEOMETRY AND HEIGHT

23 - XC29

It is the one designed for Cross-country tracks. The profile is low, and ultra light for the fastest accelerations, and the best handling. Also, we wanted it wide at 30mm internal, allowing wide tyres and low pressure.

24 - ROAD

The 24mm profile is perfect for mountain rides, hills and extreme accelerations. Its low profile naturally combines an ultra-light rim ideal for climbing, with incredible handling: perfect for descending.

40 - ROAD

It is the most versatile. At 40mm, it is primarily suitable for hilly terrain, but is also extremely light in the mountains and aerodynamic on flat tracks.

|

|

|

|

CORNERING - SNAPINESS

The combination of the 23mm profile with the ultra lightness make it super sensitive for entering curves in a precise way. Above all, it has two major assets that make it stand out from the crowd:

1. At just 315g, EXALT XC29 has a fabulous feeling of acceleration, especially on steep slopes where pedal force is intense.

2. The internal width of 30mm ensures a very favourable tyre placement with a firm hold on the beads, even if the pressure is reduced.

These two geometric and physical parameters combined ensure that EXALT XC29 delivers the best possible performance.

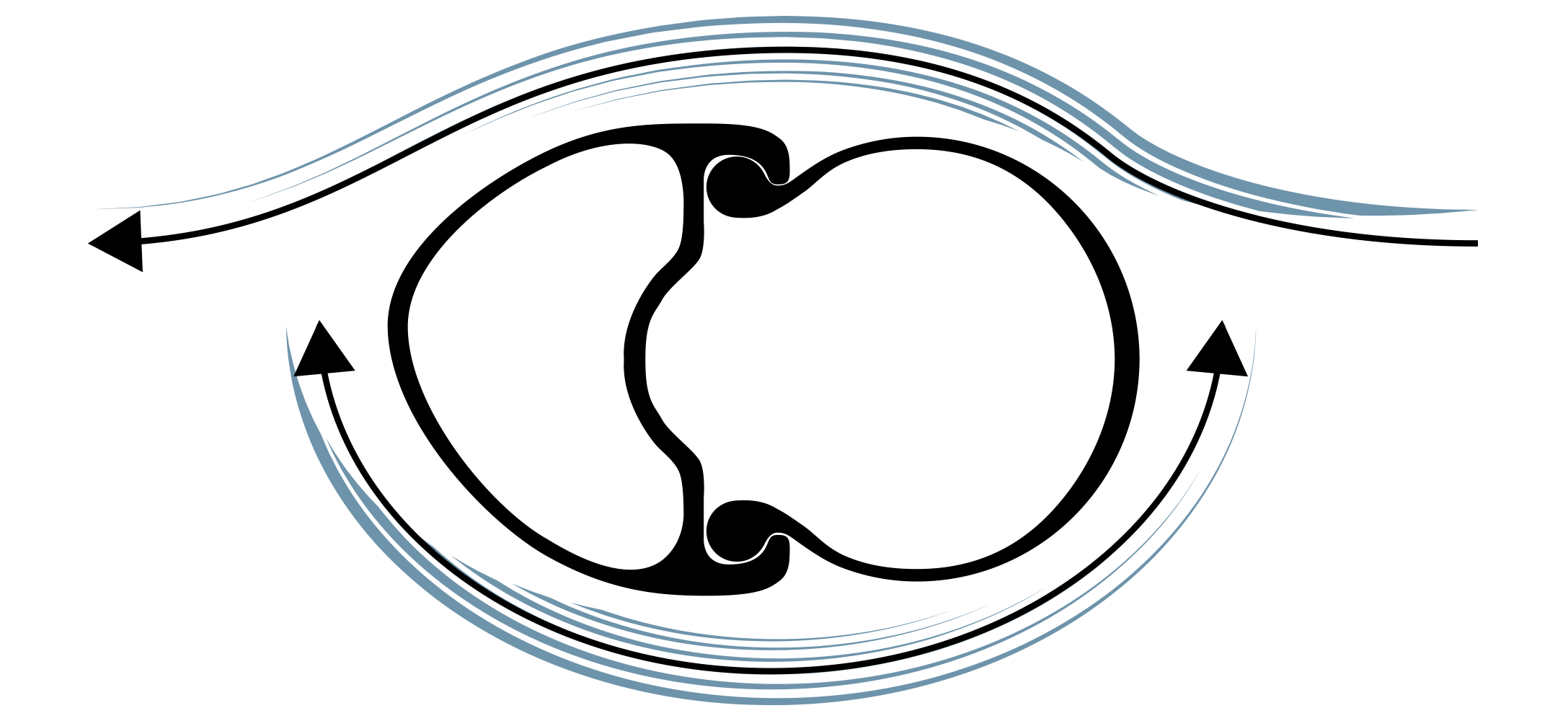

AERO - HANDLING

We have made them in the fluidest and most regular shapes.

EXALT 24 and EXALT 40 get 21mm wide between hooks, for 28mm external.

Double aim.

1. The tyres naturally widens compared to their nominal section. A 25 increases to 26, or even 26.5mm, while obviously weighting the same.

2. The air flows along the tyre/rim interface smoothly. The energy saving is real.

The interface tyre/rim section is somewhat oblong for the 40 profile, and the 24 is quite round meaning the side wind impacts the steering very few, and above all, in a totally predictable way. Indeed, the round profile generates an identical sensitivity to the airflow, whatever its direction. It was one of our objectives when designing the shape.

DYNAMICAL BALANCE

Beside the handling technical choices, we aimed at making the most dynamical and balanced wheels.

Our rims include, during the moulding process, a tiny part weighting in the exact same mass as an alloy valve for balancing its weight.

You can go descending at full speed trustfully.

ASYMMETRICAL SHAPE

2mm ROAD.

3mm XC29.

This rim offset corrects the clutter from the disc rotor or sprockets. The mechanical properties and the sensations are increased tenfold. The asymmetry is clearly visible on the valve hole offset from the trailing edge.

This feature improves the lateral stability of the spokes on the rim. The spokes with a moderate support on the hub are better supported: the left/right balance of the spoke tensions is favoured. The direct consequences are: a better resistance of the spokes to fatigue cycles, and an improved riding feeling.

TYRE FIT

We have rigorously followed the ETRTO requirements to decide the tyre area. Our rims are therefore safe, and the installation of the tyre, whether tubeless or not, is simplified.

CALCULATIONS - MATERIAL - LAYUP

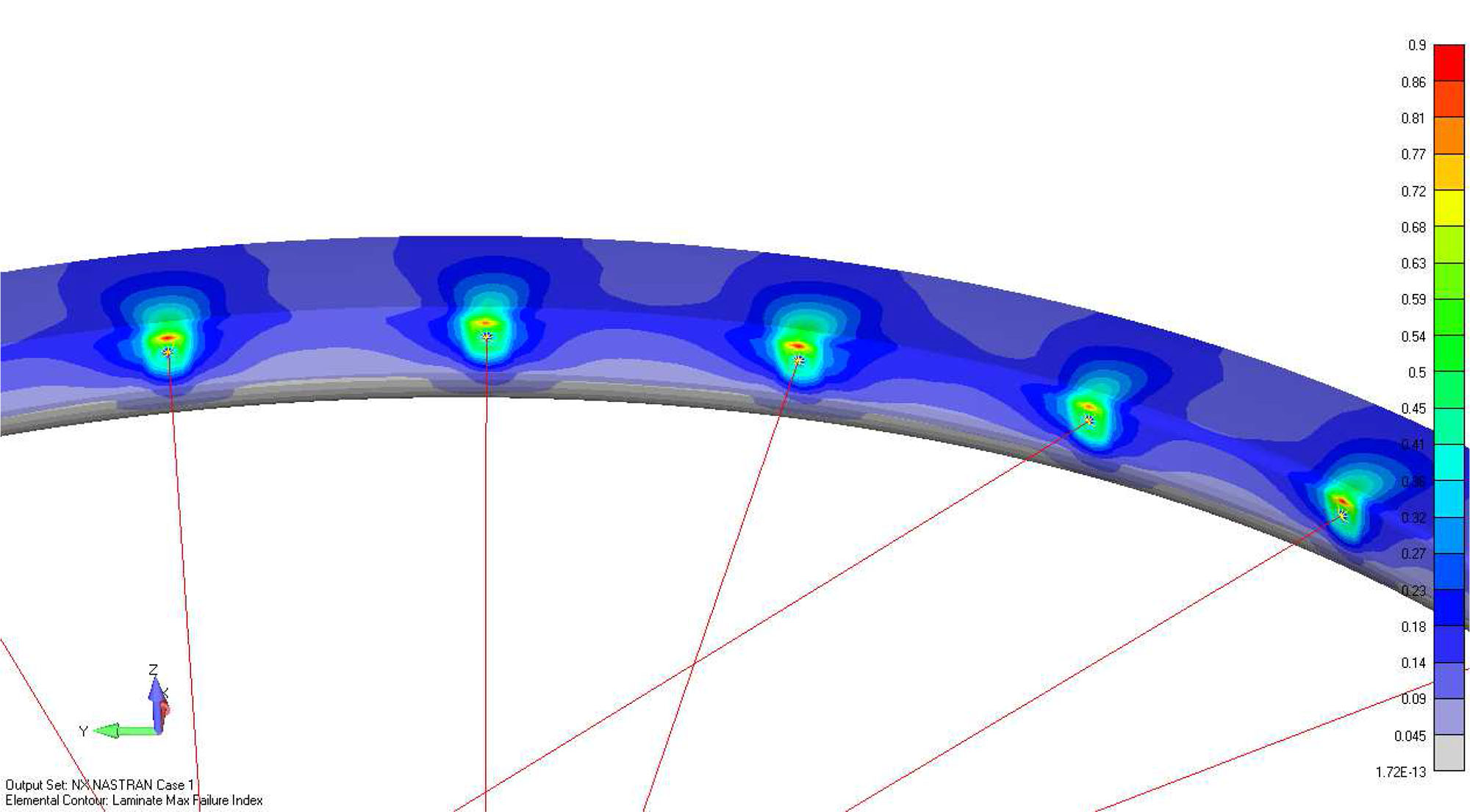

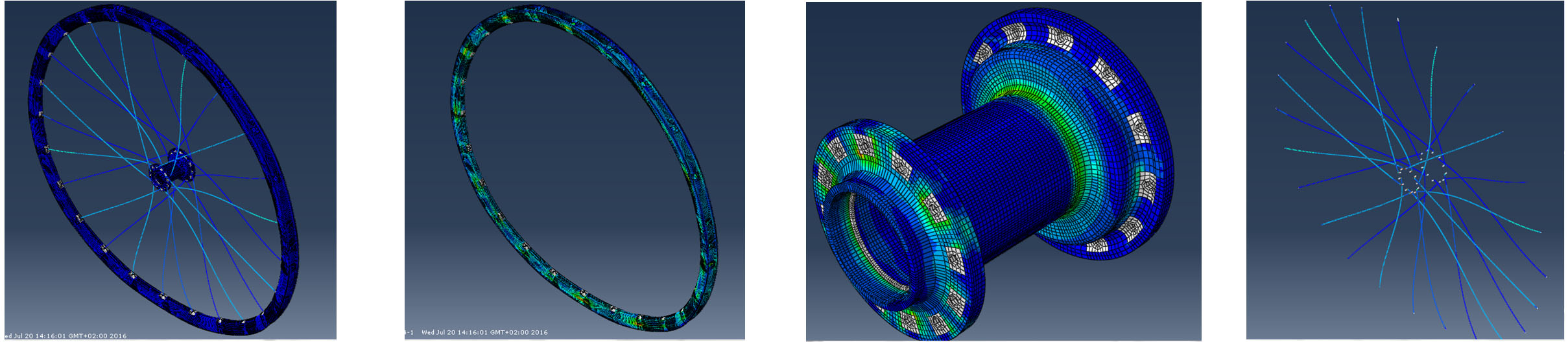

FINITE ELEMENT ANALYSIS

The fundamental stage.

The state-of-the-art composite part is primarily modelled on computer-aided design software.

The stresses are evaluated using finite element software. This part of the design highlights the mechanically stressed areas, where the composite thicknesses and ply direction must be adjusted.

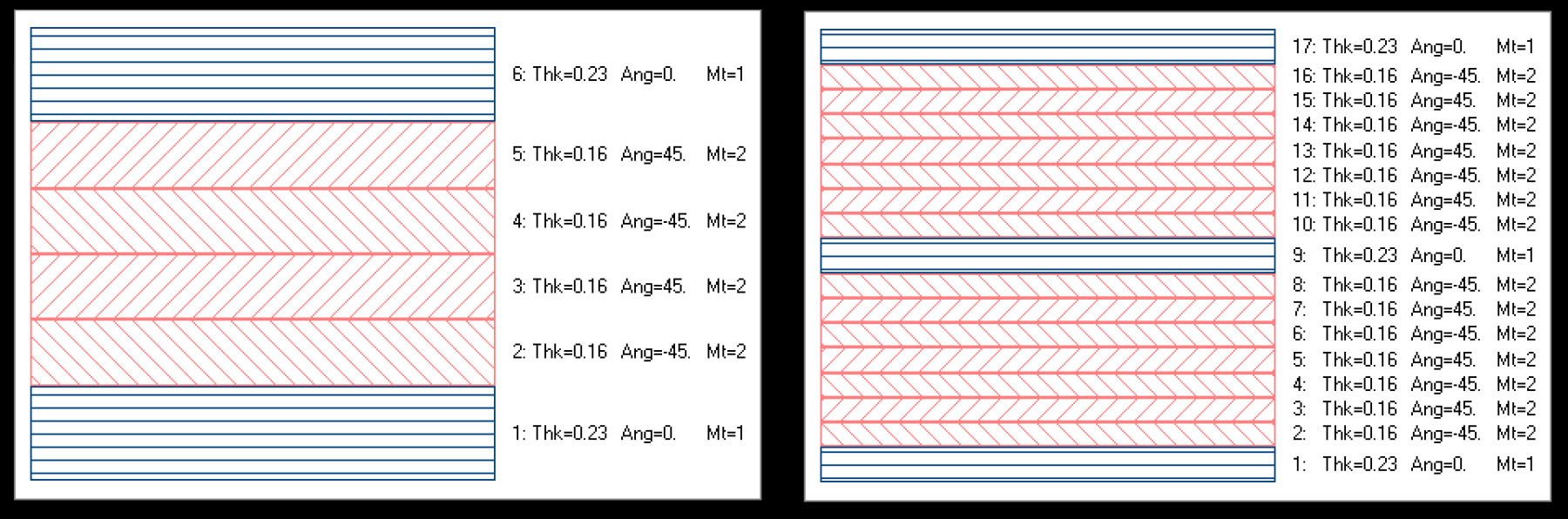

A first layout of sandwich-type pre-impregnated fabrics is favoured: it gives the part symmetrical deformation properties on each side of the profile, guaranteeing maximum strength.

The fabric layup is then modified to take into account manufacturing and application constraints, and especially the results of static and dynamic tests.

HYBRID MATERIALS

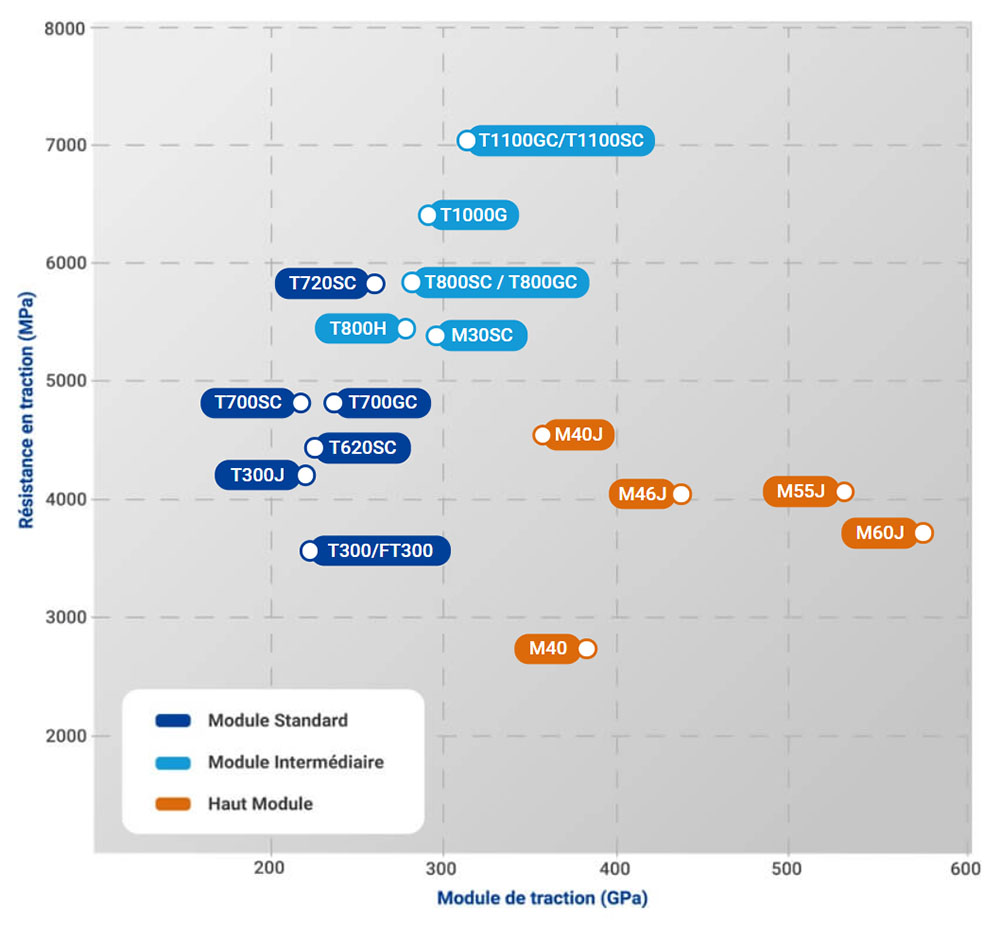

Hybrid is a term that suits our rims perfectly: the fibres selected for the production of our rims are of several types.

From the Toray catalogue, they are classified as both standard and high modulus fibres. We have optimised the properties of the rim according to the type of stress encountered, zone by zone.

They meet several criteria: performance, manufacturability and supply.

1st, performance is our historical because this is our historical path.

2nd, fabricability because the fibre must be adapted to the shape of the rim: selecting an ultra rigid fibre for performance would make no sense if it is impossible to lay it down in the mould.

3rd, supply for three reasons. Some fibres are available in unsuitable volumes. The aerospace industry purchases a wide part of the production and above all the military industry prohibits access to certain fibres.

In concrete terms, our rims are manufactured mainly from uni-directional T700+T800 fibres, which give them excellent strength and rigidity properties. In addition, we use identical 3K fabric cloth to optimise impact resistance.

We have recently introduced a new high modulus fibre to our RAR EXALT rims, the M40J, which offers a 63% increase in modulus of stiffness over T700, resulting in both increased lateral stiffness of the rim and reduced weight.

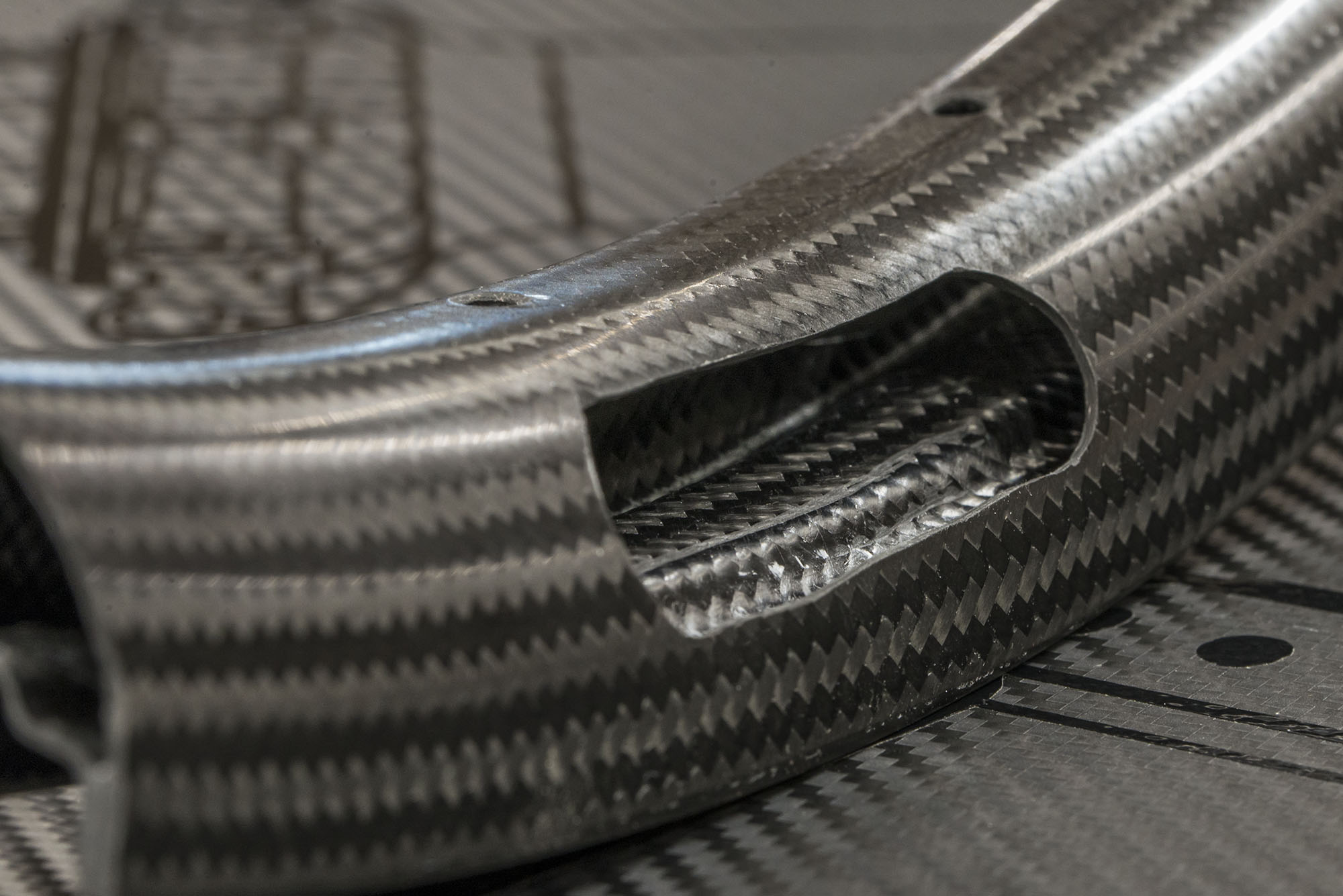

TOOLING & PRODUCTION

The engineering that goes into the development of the tooling is crucial to the production of a composite rim.

It is this tooling that makes the production efficient and reliable.

It is this tooling that gives the part its technical properties.

There are three main stages in the manufacture of the rim. Laying the pre-impregnated fabrics in the mould, curing in an oven and demoulding the finished part.

Therefore, we decided to machine down our RAR EXALT and RAR EVEN tooling into steel material that has the best characteristics of expansion at temperature, pressure and durability. This will ensure a composite part with the tightest tolerances.

The tooling is machined from a huge block of steel and is divided into several parts. Two form each rim sidewall, and the others create the rim base area plus the tyre holding hooks.

Together with our long-standing partner, we have developed a new process that enables us to produce RAR EXALT rims of unprecedented mass.

The experience of years of production allows us today to target precisely and with the greatest reliability, the zones where the thickness of the composite can be minimised.

Of course, we do not go into the details of this process. However, you should know that this technique allows us, in a very rigorous way, to refine the areas with little stress and to reinforce those that are stressed.

The first step in the production of a rim is to place the fibres in the tooling, and to fit the inflatable bladder. Pressurised to over 12 atmospheres, it presses the fibres and resin against the walls of the mould.

The second step is to cure this matrix in a temperature controlled oven. The fibres and resin then form a single piece. We use resins with a glass transition temperature of 120°C for disc brake rims.

The friction induced by the brake pads on rim brake rims requires a special matrix that maintains its strength and holds the composite fibres well above 200°C. The glass transition temperature of their resin exceeds 260°C, and the rims are post-cured to lock in these properties.

After production, we remove the bladder from the rim to lighten and facilitate assembly.

The rims are drilled at an angle to the incoming spoke.

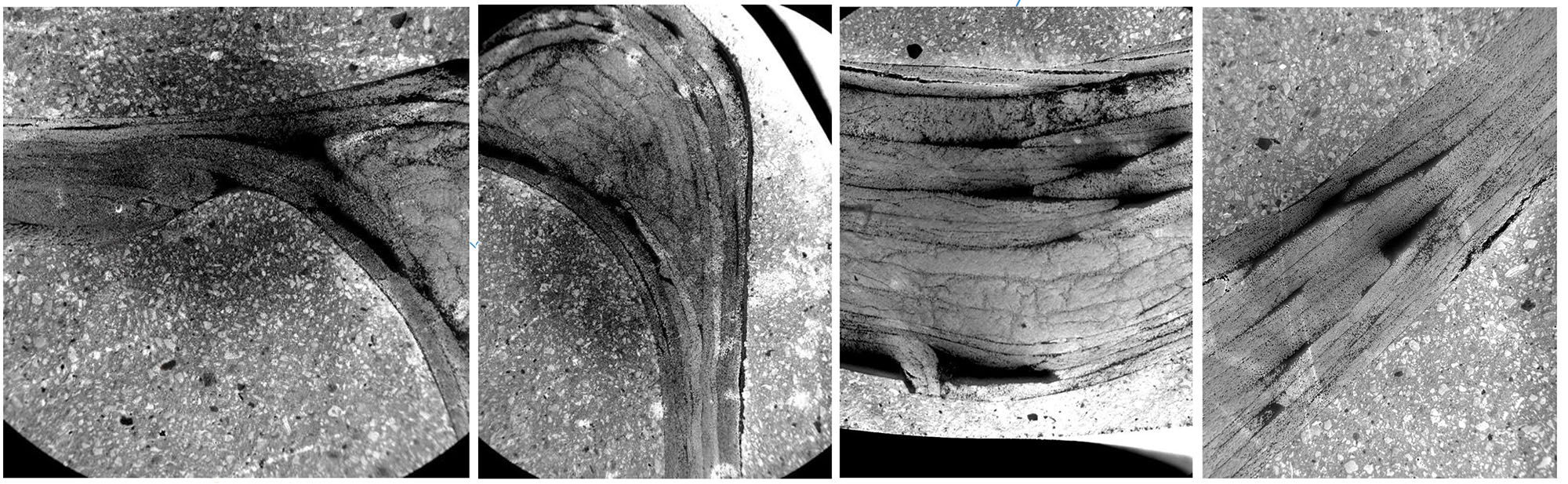

CONTROLS and TESTS

The current technical properties of the RAR EXALT and RAR EVEN rims are the result of a long development phase during which we have highlighted numerous production difficulties.

The angular shapes of the rim profiles, their circular forms, and the use of prepreg fabrics require a complex construction process which inevitably generates defects which can be of several types:

1. Inter-ply bubbles

2. Plies shift from each other

3. Layers shift around the profile

4. Left/right asymmetry of profiles

5. Areas of under or over thickness

6. Variability of vibration frequencies around the circumference

We eliminated each of these as we tested and prototyped.

Section of rim under scanning electron microscope

Section of rim under scanning electron microscope

SPECIFICATIONS

As a manufacturer since 2007, we give a lot of importance to servicing and maintenance: EVEN and EXALT rims have external nipples.

The wheel performance and the way they roll mainly depend on the rotating weight: which is the moment of inertia. We use an ultra-light rim tape that is particularly resistant over time to seal the tubeless tyre interface. This rim tape is fully compatible with tube tyres.

| EXALT clincher-tubeless |

EXALT tubular |

EXALT XC29 |

|||

| Height (mm): | 24 | 40 | 24 | 40 | 23 |

| External width (mm): | 28 | 28 | 28 | 28 | 35 |

| Internal width (mm): | 21 | 21 | - | - | 30,5 |

| Asymmetry (mm): | 2 | 2 | 2 | 2 | 3 |

| Holes: | 24 | 24 | 24 | 24 | 28 |

| Weight (g): | 310 | 350 | 230 | 290 | 315 |